-

Call Us

-

Email Us

-

Certification Number

ISO 9001:2015

- Get A Quote

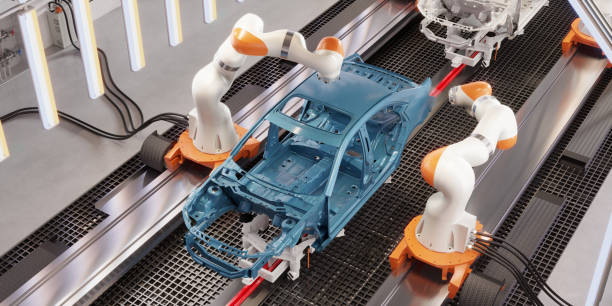

OM Sai Group offers cutting-edge automatic painting services tailored to meet diverse industrial needs. Utilizing advanced spray-painting technology, our process ensures a flawless, high-quality finish for various applications, including automotive components, furniture, and metal doors.

Also, it leverages advanced technology and equipment to deliver a superior-quality finish. The process typically occurs in a painting booth, a controlled environment enclosed by a ceiling, floor, and walls to ensure precision and safety during application. A movable spray gun is the primary mechanism that applies paint evenly across the object's surface. This spray gun is managed by an external control unit, which oversees its movement and consistency. Compressed air plays a vital role in this process by atomizing the paint particles and directing them onto the target surface, while the airbrush size determines the fineness of the spray and the pattern it produces.

Automatic spray painting is highly versatile and widely used in automotive parts, furniture, doors, and two-wheelers. This method offers several significant advantages. First, it increases production efficiency by reducing the reliance on manual labor, which translates into faster production rates. Second, it ensures consistent quality across multiple products, as the automated system eliminates the inconsistencies associated with human operation. Finally, it reduces material waste through electrostatic spray techniques, which minimize overspray and enhance paint adhesion to the surface. These painting lines can be customized to meet specific production demands, making them a safe, efficient, and environmentally friendly option for modern manufacturing.

Our state-of-the-art painting booths and automated systems deliver consistent results while minimizing waste through techniques like electrostatic spraying. Designed for efficiency, our customizable painting lines enhance production rates without compromising quality, making them ideal for large-scale operations.

- Consistent and high-quality finishes

- Customizable lines to fit client requirements

- Reduced waste through eco-friendly processes