-

Call Us

-

Email Us

-

Certification Number

ISO 9001:2015

- Get A Quote

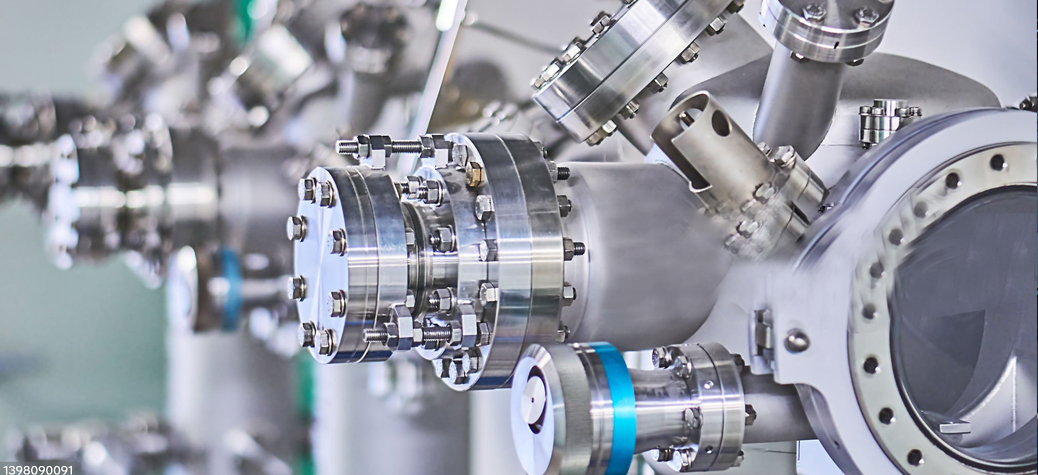

We deliver advanced PVD vacuum coating services that create high-quality, thin-film coatings for various applications. Using techniques such as thermal evaporation, sputtering, and pulsed laser deposition, we produce durable, wear-resistant, and visually appealing finishes.

Physical vapor deposition (PVD) is a cutting-edge technique for applying thin films to surfaces through the vaporization of solid materials in a vacuum. Various methods, such as thermal evaporation, sputtering, and arc deposition, are used to heat the source material until it vaporizes and condenses on the target substrate. The result is a durable, uniform coating that enhances the substrate's properties.

PVD coatings are known for their high hardness, wear resistance, and aesthetic appeal. Applications range from decorative finishes on consumer goods to functional coatings on tools and components requiring enhanced durability. While the process offers numerous benefits, including the ability to apply coatings at low temperatures and achieve excellent adhesion, it is also associated with high equipment costs and longer processing times. Skilled operators are required to manage the complex machinery and ensure quality results.

Our PVD coatings are ideal for automotive, electronics, and decorative industries, ensuring long-lasting performance and premium aesthetics. With cutting-edge technology and skilled professionals, we guarantee precise and reliable results for every project.

- Provides wear-resistant and durable finishes.

- Ideal for automotive, electronics, and decorative products.

- Uses advanced deposition techniques for precision.

- Offers aesthetically pleasing metallic finishes.